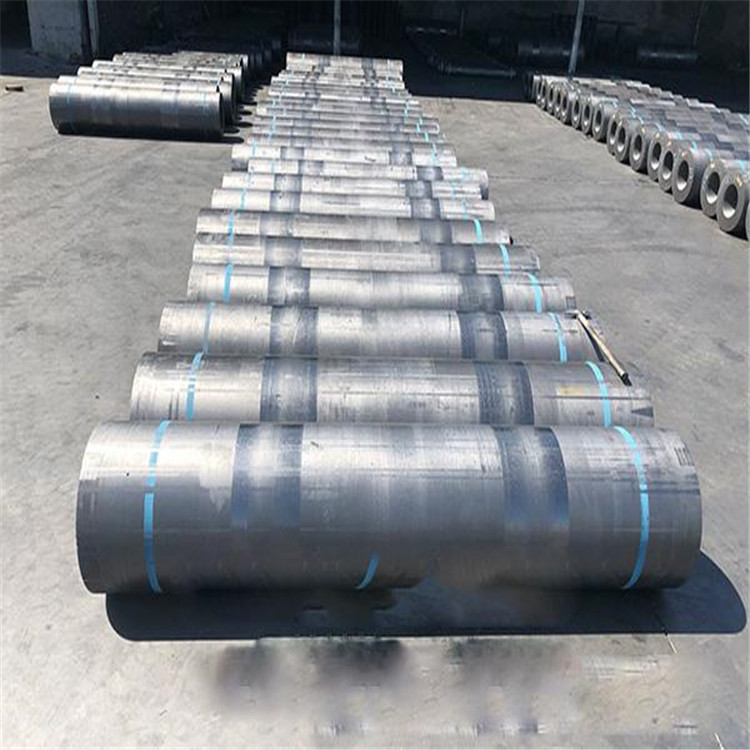

Graphite Electrodes

Electrodes-ka graphite waxa loo isticmaalaa warshadaha dhalaalista korantada waxayna leeyihiin sifooyin ay ka mid yihiin awooda sare, socodka kulaylka, xoogga farsamada sare, iska caabinta oksaydhka, iyo iska caabinta daxalka heerkulkiisu sarreeyo.

Electrodes graphite our waxay leeyihiin iska caabin hooseeya, cufnaanta sare, caabbinta oksaydhka sare, iyo saxnaanta mashiinka saxda ah, gaar ahaan baaruud hoose iyo dambas hooseeya, taas oo aan keeni doonin wasakh labaad birta.

Graphite waxay leedahay xasilooni kiimikaad oo wanaagsan. Garaafyada sida gaarka ah loo daweeyay ayaa leh astaamaha iska caabbinta daxalka, kulaylka wanaagsan ee kuleyliyaha, iyo xajinta hoose.

Qalabka graphite electrode-ka ceeriin wuxuu qaataa baaruud hoose iyo dambas yar oo CPC ah. Ku dar 30% coke irbadda heerka koronto-galka HP ee asphalt warshadda coking. UHP graphite electrodes waxay isticmaalaan 100% coke irbadda waxaana si weyn loogu isticmaalaa LF. Foornada kicinta birta samaynaysa, foornada birta ee aan birta ahayn. Warshadaha Silicon iyo Fosfooraska.

| Baaxadda UHP iyo Dulqaadka | ||||||||||||

| Dhexroorka (mm) | Dhererka (mm) | |||||||||||

| Dhexroorka magacaaban | Dhexroorka dhabta ah | Dhererka magacaaban | Dulqaad | Dhererka cagaha gaaban | ||||||||

| mm | inji | max | min | mm | mm | max | min | |||||

| 200 | 8 | 209 | 203 | 1800/2000/ 2200/2300 2400/2700 | ± 100 | -100 | -275 | |||||

| 250 | 10 | 258 | 252 | |||||||||

| 300 | 12 | 307 | 302 | |||||||||

| 350 | 14 | 357 | 352 | |||||||||

| 400 | 16 | 409 | 403 | |||||||||

| 450 | 18 | 460 | 454 | |||||||||

| 500 | 20 | 511 | 505 | |||||||||

| 550 | 22 | 556 | 553 | |||||||||

| 600 | 24 | 613 | 607 | |||||||||

| Tilmaanta Jirka iyo Kiimikada ee UHP | ||||||||||||

| Walxaha | unug | Dhexroorka: 300-600mm | ||||||||||

| Heerka | Xogta tijaabi | |||||||||||

| Electrode | Ibta naaska | Electrode | Ibta naaska | |||||||||

| Iska caabin koronto | μQm | 5.5-6.0 | 5.0 | 5.0-5.8 | 4.5 | |||||||

| Xoog dabacsanaan | Mpa | 10.5 | 16 | 14-16 | 18-20 | |||||||

| Hababka bartinimada | GPA | 14 | 18 | 12 | 14 | |||||||

| nuxurka dambaska | % | 0.2 | 0.2 | 0.2 | 0.2 | |||||||

| Cufnaanta muuqata | g/cm3 | 1.64-16.5 | 1.70-1.72 | 1.72-1.75 | 1.78 | |||||||

| Qodobka ballaarinta (100-600 ℃) | x10-6/°℃ | 1.5 | 1.4 | 1.3 | 1.2 | |||||||

S: Ka waran baakadda?

1. Sanduuqyada kartoonnada dhoofinta caadiga ah / sanduuqyada alwaaxda

2. Calaamadaha dhoofinta ee gaarka ah

3. Haddii habka baakadku aanu ku filnayn badbaado, waaxda QC ayaa samayn doonta kormeer