Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Crucibles-ku-xidhan Resin Isku darka Silicon Carbide iyo Dhoobada Graphite

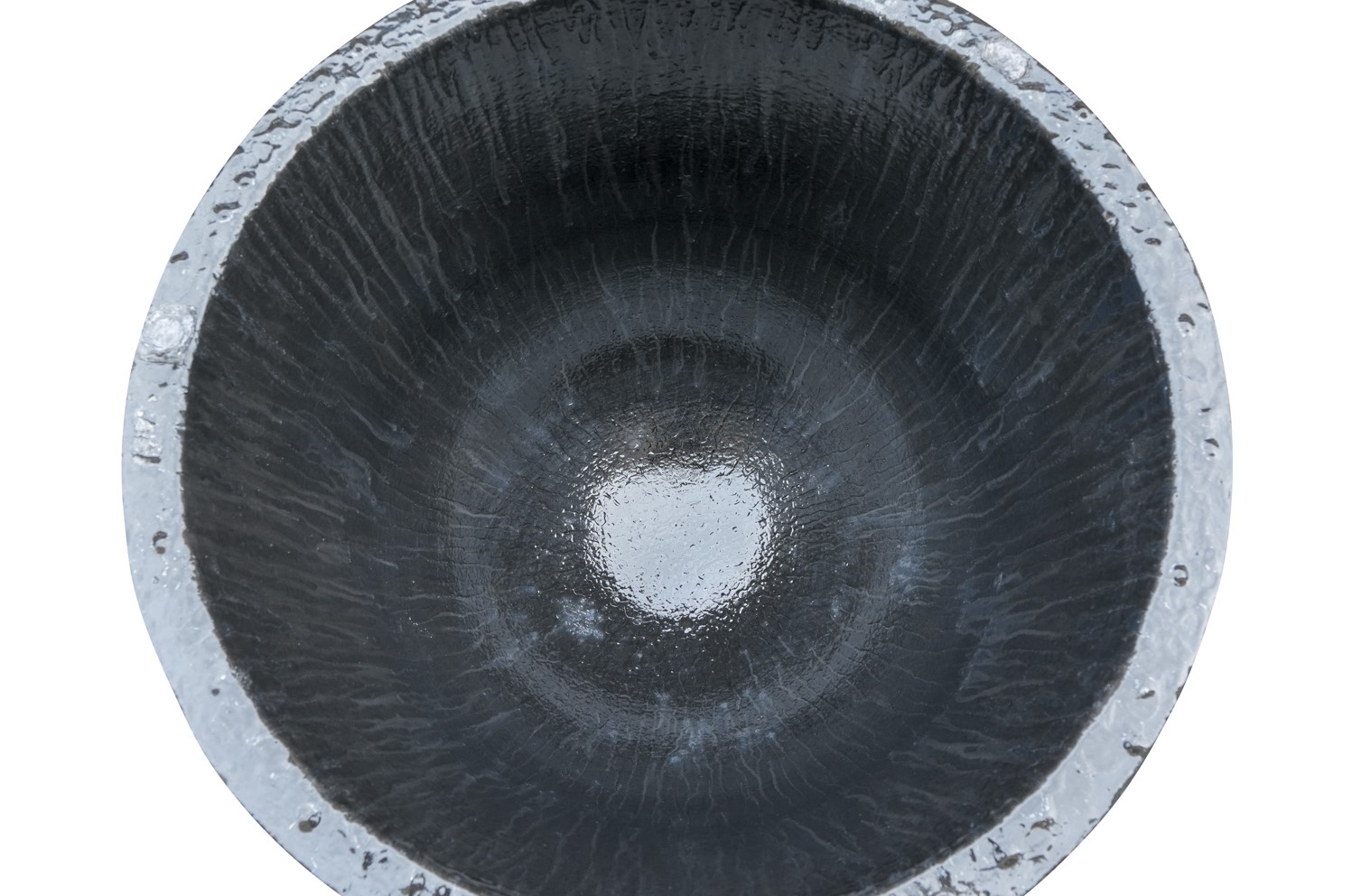

MUUQAALKA WAX soo saarka

Dhalasho degdeg ah

Qalabka garaafiga ah ee kulaylka sare wuxuu hagaajiyaa waxtarka kulaylka 30%, si weyn u yareynaya wakhtiga dhalaalka.

Iska caabinta shoogga kulaylka sare

Tiknoolajiyada isku xidhan ee resin-ku-xidhan waxay u adkeysanaysaa kuleylka iyo qaboojinta degdega ah, taasoo u oggolaanaysa in si toos ah loo dallaco iyada oo aan dillaacin.

Joogteynta Gaarka ah

Awoodda farsamada sare waxay ka hortagtaa saameynta jirka iyo nabaad guurka kiimikaad ee nolosha adeegga dheer.

QEEXIDDA FARSAMADA

| Garaaf /% | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Cufnaanta badan / g·cm⁻³ | 2.20 |

| Borosity muuqda / % | 10.8 |

| Awood burburin/MPa (25 ℃) | 28.4 |

| Qaabka dillaacsan/MPa (25 ℃) | 9.5 |

| heerkulka iska caabinta dabka / ℃ | >1680 |

| Iska caabin shoog kulaylka / Times | 100 |

| No | Qaabka | H | OD | BD |

| RA100 | 100# | 380 | 330 | 205 |

| RA200H400 | 180 # | 400 | 400 | 230 |

| RA200 | 200# | 450 | 410 | 230 |

| RA300 | 300# | 450 | 450 | 230 |

| RA350 | 349# | 590 | 460 | 230 |

| RA350H510 | 345# | 510 | 460 | 230 |

| RA400 | 400# | 600 | 530 | 310 |

| RA500 | 500# | 660 | 530 | 310 |

| RA600 | 501# | 700 | 530 | 310 |

| RA800 | 650# | 800 | 570 | 330 |

| RR351 | 351# | 650 | 420 | 230 |

HABKA NIDAAMKA

1. Habka saxda ah

Garaafka saafiga ah ee sareeya + silikoon carbide oo qaali ah + wakiilka xidhidh ee gaarka ah.

.

2.Isostatic Pressing

Cufnaanta ilaa 2.2g/cm³ | Dulqaadka dhumucda gidaarka ± 0.3m

.

3. Heerkulka Sare ee Sintering

Dib-u-kristalaynta walxaha SiC oo samaynaysa qaab-dhismeedka shabakadda 3D

.

5.Kormeer Tayo Adag

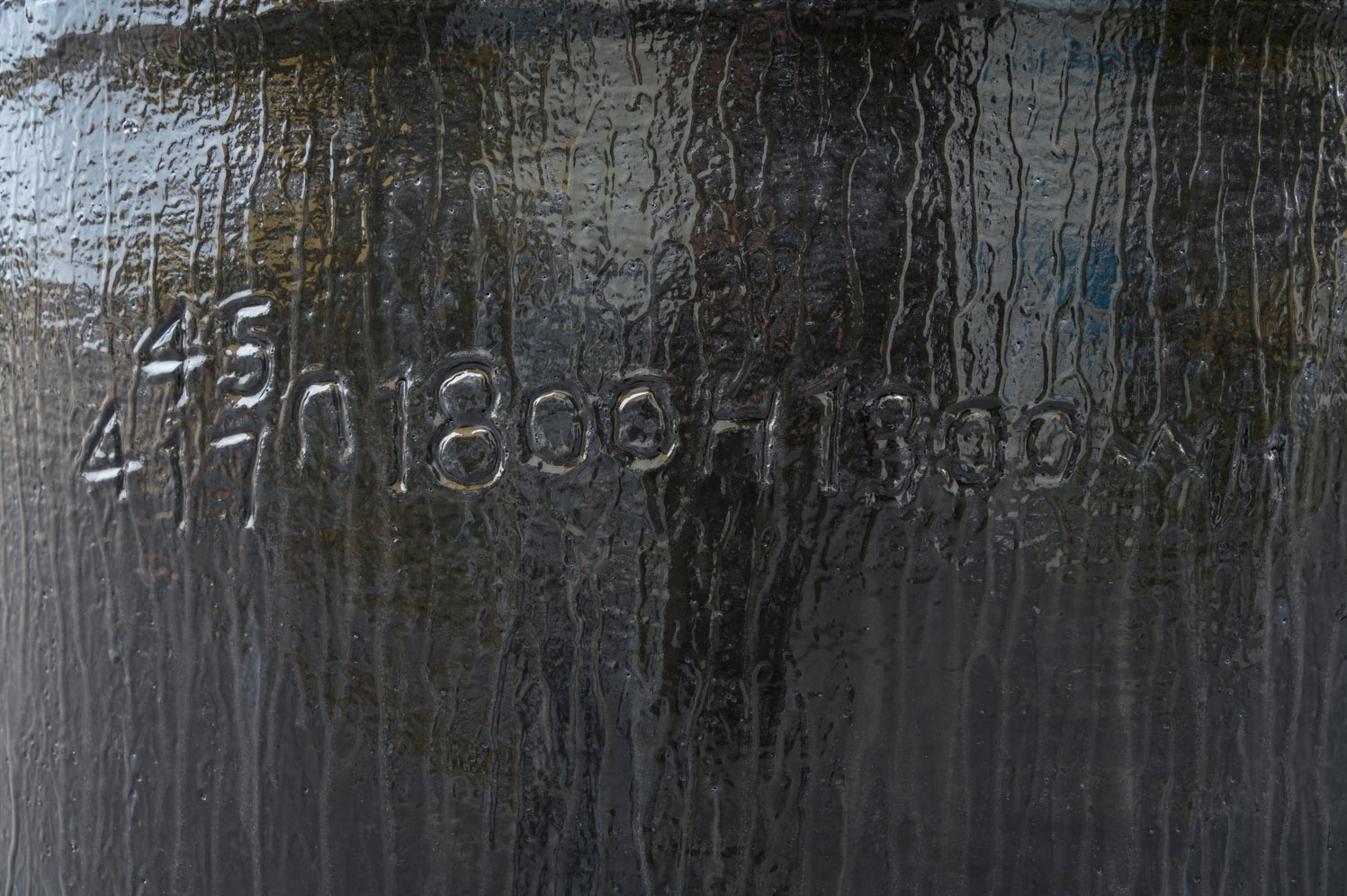

Koodhka raadraaca gaarka ah ee raadraaca nololeed ee buuxa

.

4. Kordhinta Dusha sare

Daahan ka-hortagga oksaydhka → 3 × caabbinta daxalka oo hagaagtay

.

6.Baakadaha Badbaadada

Lakabka naxdinta leh + xannibaadda qoyaanka + daboolka la xoojiyay

.

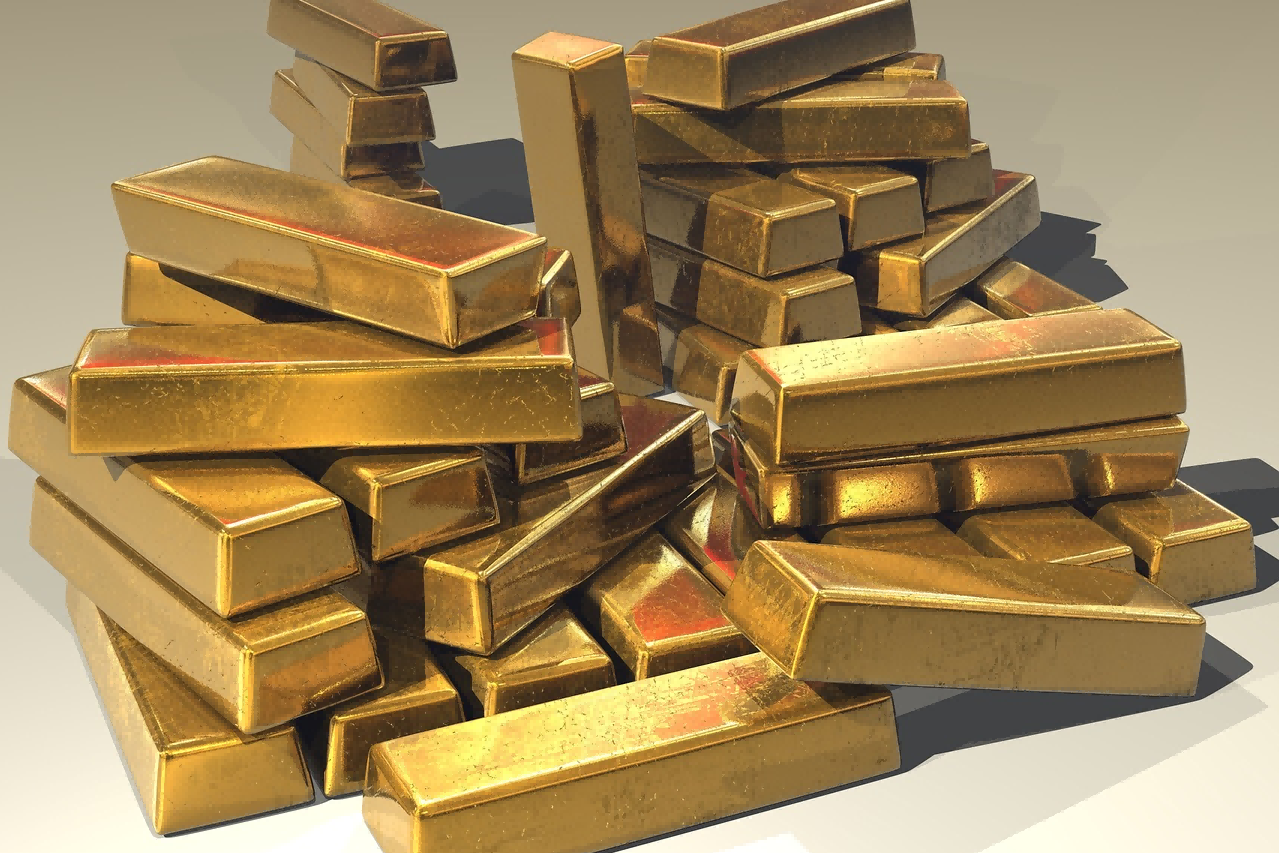

CODSIGA SOO SAARKA

Ku habboon inta badan biraha aan birta ahayn

Aluminium dhalaalaysa

Maarta dhalaalaysa

Dahab dhalaalay

MAXAA NOO DOORANAYA

FAQS

Q1: Daboolka Crucible ma yarayn karaa kharashka tamarta?

J: Dhab ahaantii! Waxay yaraynaysaa luminta kulaylka, waxay dhimaysaa isticmaalka tamarta ilaa 30%.

Q2: Waa maxay foornooyinka ku habboon?

J: Waa wax badan-ku-habboon soo-gelinta, gaaska, iyo foornooyinka korontada.

Q3: Garaafyada silikoon carbide ma ammaan u yahay heerkulka sare?

J: Haa. Deganaansho kuleylkeeda iyo kiimiko ayaa ka dhigaysa mid ku habboon xaaladaha daran.

Q4: Sidee looga hortagi karaa dildilaaca?

Waligaa ha ku dallacin walxo qabow weel kulul (max ΔT <400°C).

Heerka qaboojinta kadib dhalaalid <200°C/saacaddii.

Isticmaal suumanka qashinka ah ee go'an (iska ilaali saamaynta farsamada).

Q5Sidee looga hortagi karaa dildilaaca?

Waligaa ha ku dallacin walxo qabow weel kulul (max ΔT <400°C).

Heerka qaboojinta kadib dhalaalid <200°C/saacaddii.

Isticmaal suumanka qashinka ah ee go'an (iska ilaali saamaynta farsamada).

Q6Waa maxay tirada dalabka ugu yar (MOQ)?

Qaababka caadiga ah: 1 gabal (muunado la heli karo).

Nakhshad gaar ah: 10 xabbo (sawir CAD ayaa loo baahan yahay).

Q7Waa maxay wakhtiga hogaanka?

⏳Alaabta Kaydka Ah: Ku soo qaada 48 saacadood gudahood.

⏳Dalabka gaarka ah: 15-25maalmowax soo saarka iyo 20 maalmood ee caaryada.

Q8Sidee loo go'aamiyaa haddii qoloftu fashilantay?

Dildilaaca> 5mm gidaarka gudaha.

Qoto galinta birta>2mm.

Qallafsanaanta> 3% (cabir dhexroorka sare ee isbeddelka).

Q9Ma bixisaa hagitaan habka dhalaalka?

Curyaaminta kuleylka ee biraha kala duwan.

Xisaabiyaha heerka socodka gaaska aan shaqayn.

Casharrada fiidiyoowga ah ee ka saarista Slag.

Daraasadda Kiis #1

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Daraasadda Kiis #2

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante.

Markhaati

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, iyo feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis.

- Jane Doe

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec feugiat ultricies vulputate. Suspendisse quis lacinia erat, eu tincidunt ante. Pellentesque aliquet feugiat tellus, iyo feugiat tortor porttitor vel. Nullam id scelerisque magna. Curabitur placerat sodales placerat. Nunc dignissim ac velit vel lobortis. Nam luctus mauris elit, sed suscipit nunc ullamcorper ut.

- John Doe