Sic Crucibles ee foornada dhalada

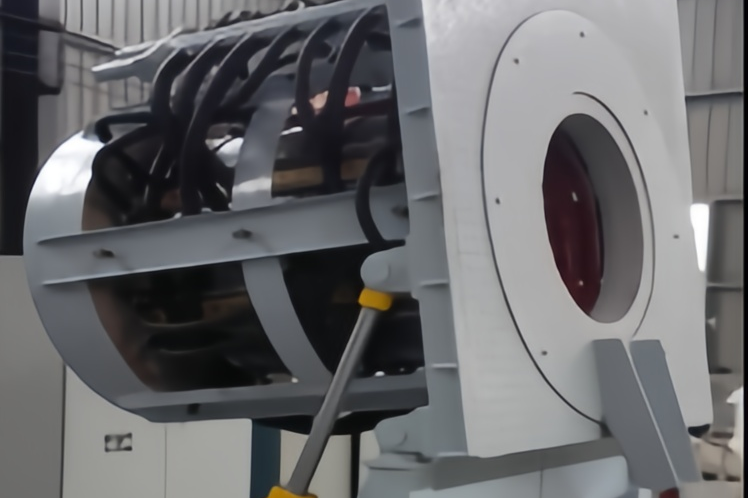

MUUQAALKA WAX soo saarka

Habdhaqanka Kulaylka Sare

Isku dhafka gaarka ah ee silikoon carbide iyo graphite waxay hubisaa kuleyl degdeg ah oo isku mid ah, si weyn u yareynaya waqtiga dhalaalka.

Iska caabin heerkul aad u daran

Isku dhafka gaarka ah ee silikoon carbide iyo graphite waxay hubisaa kuleyl degdeg ah oo isku mid ah, si weyn u yareynaya waqtiga dhalaalka.

Iska caabinta Daxalka waara

Isku dhafka gaarka ah ee silikoon carbide iyo graphite waxay hubisaa kuleyl degdeg ah oo isku mid ah, si weyn u yareynaya waqtiga dhalaalka.

QEEXIDDA FARSAMADA

| Garaaf /% | 41.49 |

| SiC / % | 45.16 |

| B/C / % | 4.85 |

| Al₂O₃ / % | 8.50 |

| Cufnaanta badan / g·cm⁻³ | 2.20 |

| Borosity muuqda / % | 10.8 |

| Awood burburin/MPa (25 ℃) | 28.4 |

| Qaabka dillaacsan/MPa (25 ℃) | 9.5 |

| heerkulka iska caabinta dabka / ℃ | >1680 |

| Iska caabin shoog kulaylka / Times | 100 |

| Qaabka/Foomka | A (mm) | B (mm) | C (mm) | D (mm) | E x F ugu badnaan (mm) | G x H (mm) |

|---|---|---|---|---|---|---|

| A | 650 | 255 | 200 | 200 | 200x255 | Marka la codsado |

| A | 1050 | 440 | 360 | 170 | 380x440 | Marka la codsado |

| B | 1050 | 440 | 360 | 220 | 380 | Marka la codsado |

| B | 1050 | 440 | 360 | 245 | 440 | Marka la codsado |

| A | 1500 | 520 | 430 | 240 | 400x520 | Marka la codsado |

| B | 1500 | 520 | 430 | 240 | 400 | Marka la codsado |

HABKA NIDAAMKA

1. Habka saxda ah

Garaafka saafiga ah ee sareeya + silikoon carbide oo qaali ah + wakiilka xidhidh ee gaarka ah.

.

2.Isostatic Pressing

Cufnaanta ilaa 2.2g/cm³ | Dulqaadka dhumucda gidaarka ± 0.3m

.

3. Heerkulka Sare ee Sintering

Dib-u-kristalaynta walxaha SiC oo samaynaysa qaab-dhismeedka shabakadda 3D

.

4. Kordhinta Dusha sare

Daahan ka-hortagga oksaydhka → 3 × caabbinta daxalka oo hagaagtay

.

5.Kormeer Tayo Adag

Koodhka raadraaca gaarka ah ee raadraaca nololeed ee buuxa

.

6.Baakadaha Badbaadada

Lakabka naxdinta leh + xannibaadda qoyaanka + daboolka la xoojiyay

.

CODSIGA SOO SAARKA

Foornada Gaaska dhalaalaysa

Foornada dhalaalaysa ee Induction

Foornada dhalaalaysa iska caabinta

MAXAA NOO DOORANAYA

FAQS

Q1: Waa maxay faa'iidooyinka silikoon carbide graphite crucibles marka la barbar dhigo garaafyada garaafka dhaqameed?

✅Cadaadiska Heerkulka Sare: Wuxuu u adkeysan karaa 1800°C waqti dheer iyo 2200°C waqti gaaban (marka loo eego ≤1600°C ee garaafyada).

✅Cimri dheer: 5x iska caabin shoog kulaylka ka fiican, 3-5x celceliska nolosha adeeg dheer.

✅Wax wasakhaysan eber: Ma jiro wax kaarboon dhex gala, hubinta nadiifnimada birta dhalaalaysa.

Q2: Waa kuwee biraha lagu dhalaali karo weelashan?

▸Biraha Caadiga ahAluminium, copper, zinc, dahab, qalin, iwm.

▸Biraha falcelintaLithium, sodium, calcium (waxay u baahan tahay daahan Si₃N₄).

▸Biraha Refractory: Tungsten, molybdenum, titanium (waxay u baahan tahay vacuum/gaas aan lahayn).

Q3: Karootada cusub miyay u baahan yihiin daawayn kahor intaan la isticmaalin?

Dubista qasabka ah: Si tartiib ah uguleyl ilaa 300°C → hay 2 saacadood (waxay ka saartaa qoyaanka haraaga ah).

Talada Dhalasho ee Koowaad: Marka hore dhalaali qayb ka mid ah walxaha qashinka ah (waxay samaysaa lakab difaac).

Q4: Sidee looga hortagi karaa dildilaaca?

Waligaa ha ku dallacin walxo qabow weel kulul (max ΔT <400°C).

Heerka qaboojinta kadib dhalaalid <200°C/saacaddii.

Isticmaal suumanka qashinka ah ee go'an (iska ilaali saamaynta farsamada).

Q5Sidee looga hortagi karaa dildilaaca?

Waligaa ha ku dallacin walxo qabow weel kulul (max ΔT <400°C).

Heerka qaboojinta kadib dhalaalid <200°C/saacaddii.

Isticmaal suumanka qashinka ah ee go'an (iska ilaali saamaynta farsamada).

Q6Waa maxay tirada dalabka ugu yar (MOQ)?

Qaababka caadiga ah: 1 gabal (muunado la heli karo).

Nakhshad gaar ah: 10 xabbo (sawir CAD ayaa loo baahan yahay).

Q7Waa maxay wakhtiga hogaanka?

⏳Alaabta Kaydka Ah: Ku soo qaada 48 saacadood gudahood.

⏳Dalabka gaarka ah: 15-25maalmowax soo saarka iyo 20 maalmood ee caaryada.

Q8Sidee loo go'aamiyaa haddii qoloftu fashilantay?

Dildilaaca> 5mm gidaarka gudaha.

Qoto galinta birta>2mm.

Qallafsanaanta> 3% (cabir dhexroorka sare ee isbeddelka).

Q9Ma bixisaa hagitaan habka dhalaalka?

Curyaaminta kuleylka ee biraha kala duwan.

Xisaabiyaha heerka socodka gaaska aan shaqayn.

Casharrada fiidiyoowga ah ee ka saarista Slag.